Label Printers

Showing 1–100 of 366 results

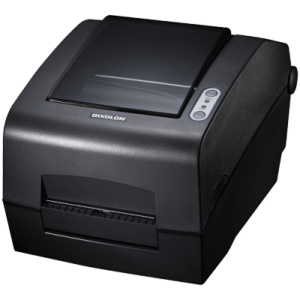

POS Barcode Label Printers/Label Makers

Labels serve the purpose of identifying and providing information about items, products, or objects. These pieces of information can include details such as barcodes, product descriptions, prices, and other relevant data. They are available in color label or black and white labels based on printer capacity.

Label printers or label makers are specialized devices designed to create and print custom labels based on options or settings available on label printer you choose. Label printers are extensively utilized across various industries, available in diverse sizes and configurations, including both wired and wireless options. Label printers, also known as sticker barcode printers are used across different industries for tasks such as generating product labels, creating shipping labels, managing inventory, and facilitating organizational processes. They play a crucial role in improving efficiency, accuracy, and organization in various sectors by producing clear and standardized labels for diverse applications.

Major label printer brands in the Australian market include Brother, DYMO, Zebra, Epson, Brady, TSC, Citizen, SATO, Honeywell, and Avery Dennison. Offering diverse solutions for industrial, retail, and personal labeling needs, these brands provide a range of models suitable for various applications, from barcode printing to product labeling.

Here are some common places where label printers are used:

- Retail: Label printers are used in retail environments for printing price tags, product labels, and barcodes.

- Manufacturing: In manufacturing, industrial label printers are used to create labels for products, components, and packaging. This helps in tracking and managing inventory.

- Logistics and Shipping: Shipping Label printers play a crucial role in logistics and shipping for generating shipping labels, tracking labels, and barcodes for packages.

- Healthcare: In healthcare settings, label printers are used to create labels for patient identification, medication labeling, and specimen tracking.

- Warehouse Management: Label printers are used in warehouses to generate labels for inventory items, storage locations, and shipping.

- Food Industry: In the food industry, label makers are employed to print labels with nutritional information, expiration dates, and batch numbers.

- Library and Education: Label printers are used in libraries and educational institutions for cataloging books and assets.

- Office: Label printers can be used in offices for creating address labels, file labels, and other organizational labels.

- Events and Conferences: Label printers are used at events and conferences for printing attendee badges and labels.

- Apparel and Textiles: In the fashion industry, label makers are used to create clothing labels with size information, care instructions, and brand details.

- Pharmaceuticals: Label printers are used in pharmaceutical industries for labeling medicine bottles, packaging, and tracking.

Label printers typically use one of the following print mechanisms:

- Direct Thermal Printing:

- How it works: Direct thermal printing uses heat-sensitive paper or labels. The print head applies heat to the paper, causing it to darken at the points where heat is applied, creating the desired image or text.

- Advantages: Simple mechanism, no need for ribbons or ink cartridges, suitable for short-term label applications.

- Applications: Commonly used for barcode labels, shipping labels, and receipts.

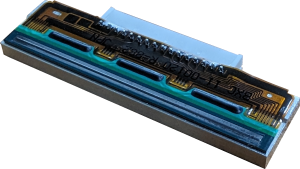

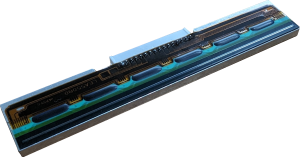

- Thermal Transfer Printing:

- How it works: Thermal transfer printing involves using a ribbon (usually wax, resin, or a combination) and applying heat to transfer ink from the ribbon to the label material, creating the printed image or text.

- Advantages: Produces durable and long-lasting prints, suitable for a wide range of label materials.

- Applications: Used for product labeling, inventory labels, and applications requiring high durability.

- Inkjet Printing:

- How it works: Inkjet label printers use liquid ink sprayed onto the label surface to create images and text. This technology is similar to standard desktop inkjet printers but adapted for label printing.

- Advantages: Full-color printing capabilities, suitable for high-quality and customizable labels.

- Applications: Commonly used for product labels, packaging, and applications requiring color graphics.

- Laser Printing:

- How it works: Laser label printers use a laser beam to create an electrostatic image on a photosensitive drum, which is then transferred to the label material and fused using heat.

- Advantages: High-speed printing, suitable for high-volume label production.

- Applications: Used for barcode labels, shipping labels, and office label printing.

The choice of print mechanism depends on factors such as the intended use of the labels, required print quality, durability, and the type of materials used for labels. Each print mechanism has its own set of advantages and is selected based on the specific needs of the application.